Master (and Wheel) Cylinder Servicing

§ Repair kits are

available and sometimes the m/c and w/c’s

can be reclaimed by re-sleeving or honing and fitting these kits

.

§ Oversize cups are

not available, as they once used to be.

§ Honing is not meant

to remove much material at all just clean up the bore which I would use

fine steel wool on first .

§

If there is any

pitting or indentations remaining in the bore caused by corrosion (or

whatever) the cylinder is not re-useable without re-sleeving.

§Fit up overhauled cylinders with special purpose

rubber grease (no mineral product allowed).

§

Keep in mind the

weakest link will fail and when that is repaired the next weakest will

fail.

§ RECOMMENDATION is

all or nothing.

§

Brakes are one area

to do best the first time and save bucks down the line.

§ Shop labour costs

in repairing will be higher than buying all new stuff and doing it

yourself.

§ Sleeving is a great

(one time expensive) option to keep original and get long, long

life.

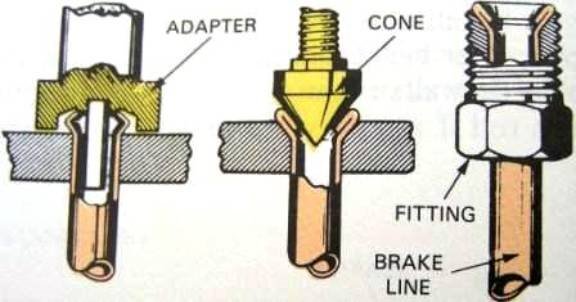

Steel Brake Lines

§ These are made up of special steel tube made for

brake lines, double flared at all extremities. They should

not be made from copper or single flared. In some cases stainless

steel lines are used when salted roads and corrosion are

issues.

Double

Flared Steel Brake Tube

§ With the right

flaring tool you can do it yourself with some practice .

§

Some little “ S ” bends are a little harder than

straight lines as we know!

§

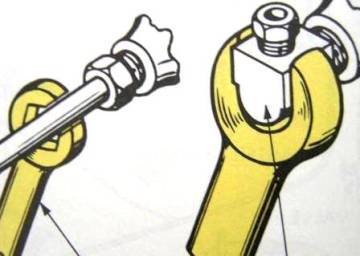

Bending

should be done with special benders and

in some cases inside coiled springs meant for that purpose .

§ Without

you will kink and ruin the tube, so

don’t try!

§

All lines

should be fixed with original type

clamping (or similar) in all original positions. Fatigue and

failure if not done properly .

Flexible Brake Lines

§

Flexible lines have

a use by date and NOS should be avoided.

§

When hand bent or

twisted if there is evidence of fatigue or perishing they should be

discarded and NEW stock ones fitted

§

Old hoses may show

up as a softer, spongy brake pedal .

§ All original style

clips and attachments must be in place .

§

Appropriate tools

and techniques should be used when removing and replacing parts

Brake

Drums

§

Original brake

drums have a slot for feeler gauge measurement on adjustment with wheels

off.

§

This facility is

not too effective with badly worn or machined drums.

§

New stock drums

sometimes don’t have these

slots (see section on

adjustment)

Feeler slot

§

Are hub mounted

using the wheel mounting studs swaged so the hub and drumjpg become one

part.

§

The drums can be

machined through various O/S to manufacturer’s limits and then replaced.

§

Drums should be

machined the same dimensions in a minimum of pairs preferably all four.

The drums and mounting studs (which are the wheel studs as well) are

serviceable.

§

The drums which

become worn beyond limits, oval and bell shaped in service if outside

specification limits need to be replaced . This requires separation of the swaged (swedged)

components .

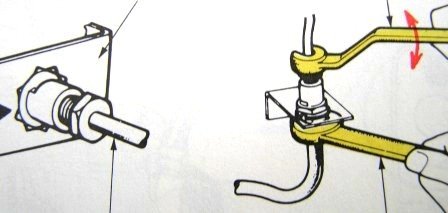

Swage Remover

Full Swage

Removal

Partial Swage

§

There are some

rough and ready ways to remove studs but I recommend you use a tool, like

this one from Bryce of “run

forest run” in a low geared

slow running drill, to relieve the effects of swaging. This will

allow you to press out the old stud more easily and safely. If you insist

on using a hammer (persuader) it will be easier and less dangerous if the

burring or swage is removed.

§

New drums and studs

should be fitted on perfectly clean flat surfaces between hub and drum and

re-swaged when installed .

§

This fitting should

be done with a press (support mounted under the wheel stud/s head/s

suggest a piece of 4” x

4” hardwood just short of the

drum dia and moving to suit) and a short piece of pipe which fits neatly

over the stud thread and just longer than the thread when fully home. Deep

socket?

§

Bushy style with a

persuader (BFH) is not recommended but some will insist.

§

Either way is

critical and if incorrectly implemented may require a complete re-do or

new drums to be skimmed to round!

Full Swage

Removal

Partial Swage

§

There are some

rough and ready ways to remove studs but I recommend you use a tool, like

this one from Bryce of “run

forest run” in a low geared

slow running drill, to relieve the effects of swaging. This will

allow you to press out the old stud more easily and safely. If you insist

on using a hammer (persuader) it will be easier and less dangerous if the

burring or swage is removed.

§

New drums and studs

should be fitted on perfectly clean flat surfaces between hub and drum and

re-swaged when installed .

§

This fitting should

be done with a press (support mounted under the wheel stud/s head/s

suggest a piece of 4” x

4” hardwood just short of the

drum dia and moving to suit) and a short piece of pipe which fits neatly

over the stud thread and just longer than the thread when fully home. Deep

socket?

§

Bushy style with a

persuader (BFH) is not recommended but some will insist.

§

Either way is

critical and if incorrectly implemented may require a complete re-do or

new drums to be skimmed to round!

Brake Linings

§

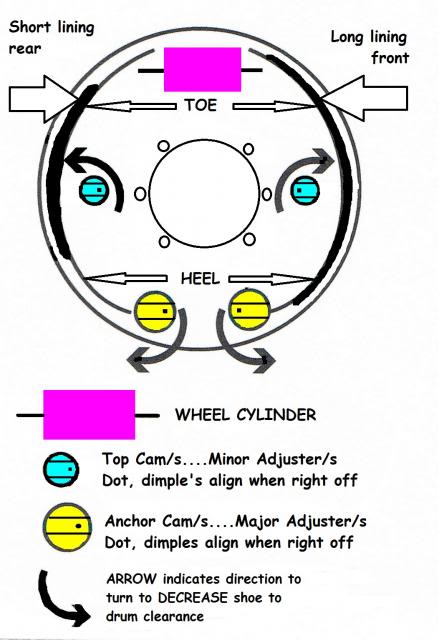

Linings can be

bonded or riveted, standard or oversize. There are two shoes leading (or front)

which is the longest and trailing (or rear) which is the shortest.

Short and long shoe

linings

§ If the brake drums

have been machined, oversize linings need to be fitted and the shoes with

new O/S linings should be cam ground to suit the drum by your preferred

brake specialist. Standard linings = poor brakes if used

with o/s drums.

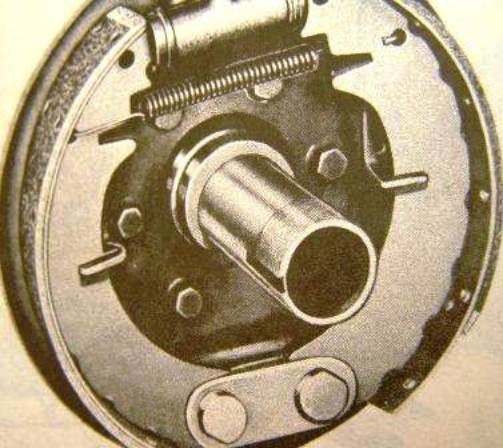

Backing Plate, Anchors,

Adjusters and Wheel Cylinders

§

Backing plates

require no service and unless mud and contaminants have fouled inside the

drum they should last the life of the vehicle and more.

§

There are two “U” guide slots riveted to each plate in which

the shoes are kept in line, rest and move. These should be free from

burrs, evident damage and wear signs.

§

Should be greased

with a lithium based product meant for that purpose e.g. “Lubeguard” which does not collect brake dust.

§

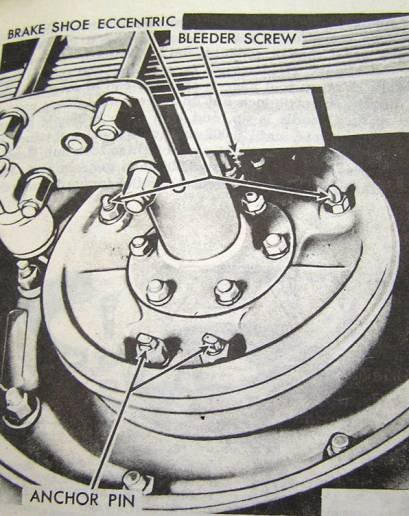

Anchors/major

eccentric adjusters are located at the bottom of and hold each shoe to the

backing plate.

§ It is a good idea

to disassemble, clean and grease as above

§

Each shoe when

mounted correctly on the adjuster has the ability to move in and out and

up and down so as to adjust symmetrically to the drum ID.

§

On the outside of

the backing plate the anchor pin adjusters have two indentations these

need to be as close together as possible on refitting and before adjusting

(See section on adjustment)

§

On the outside of

the backing plate the anchor pin adjusters have two indentations these

need to be as close together as possible on refitting and before adjusting

(See section on adjustment)

Anchor eccentric adjusters

§

Near the top of the

backing plate there are two eccentric adjusters for minor brake adjustment

(See section on adjustment)

§

Again these can be

disassembled cleaned and greased as mentioned above.

§

A brake return

spring connects both brake shoes and holds these in place mating against

the w/c piston receiving slots.

§

There are two (2)

diameter wheel cylinders and the larger 25mm (1 ”) is always fitted to the front axle as more

braking force is needed there because of weight transfer.

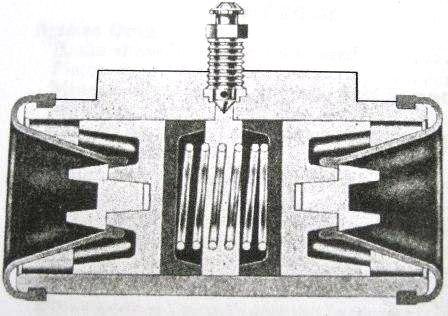

§ The w/c contains a

light spring keeping two w/c rubbers and pistons apart.

§ The flat rubber

surface fits against the flat piston surface

§ Each w/c contains a

bleed screw which most folk like to over tighten. Suggest just

nip them up, light tension put on the rubber dust cap and seal around the

thread with a thick paint. Next guy to touch, then won ’t snap them off. Curses!

§

There are

aftermarket bleeders available with a one way check valve recommended by

some to help with bleeding, especially when unassisted.

Adjustment of Jeep Brakes (hydraulic)

§ The w/c contains a

light spring keeping two w/c rubbers and pistons apart.

§ The flat rubber

surface fits against the flat piston surface

§ Each w/c contains a

bleed screw which most folk like to over tighten. Suggest just

nip them up, light tension put on the rubber dust cap and seal around the

thread with a thick paint. Next guy to touch, then won ’t snap them off. Curses!

§

There are

aftermarket bleeders available with a one way check valve recommended by

some to help with bleeding, especially when unassisted.

Adjustment of Jeep Brakes (hydraulic)

Derek’s Tools & Someone’s Improvising

Note Derek’s modified ring spanner (box

wrench)

IMPORTANT:

Before any

adjustment the foot pedal free play must be correct and the pedal return

spring in place as explained in the section on m/c

The brakes must be

normalized and not HOT.

Wheels must be off

the ground preferably on stands, in neutral, handbrake off and not

dragging.

Check shoes are not

dragging.

There are two types

of adjustment:

Minor for normal

in-service adjustment

Method: Everything

done as listed previously in IMPORTANT

Derek’s Tools & Someone’s Improvising

Note Derek’s modified ring spanner (box

wrench)

IMPORTANT:

Before any

adjustment the foot pedal free play must be correct and the pedal return

spring in place as explained in the section on m/c

The brakes must be

normalized and not HOT.

Wheels must be off

the ground preferably on stands, in neutral, handbrake off and not

dragging.

Check shoes are not

dragging.

There are two types

of adjustment:

Minor for normal

in-service adjustment

Method: Everything

done as listed previously in IMPORTANT

§

Lightly loosen the forward

located (leading) brake shoe eccentric lock nut with a ring spanner (box

wrench) and leave it in place so that you can retighten in one (1)

go. We

are talking of the top adjuster!

§

There is a special

tool (Snap On) 3/16” or

equivalent metric OE wrench (my kit does not go down that far) and at

worse a 100mm (4”) shifter or

adjustable and no bigger will do the job.

§

“If” the top adjuster has a dimple and it is away

from the wheel, the cam is off

§

The adjuster should

not feel real tight, if it does loosen the lock nut further (slightly) and

do not get a bigger (more leverage) type tool 3-4” is enough.

§

Usually you are not

turning too much but should the thread tend to tighten the locknut, loosen

a little more.

§

The cam is

symmetrical so you can turn either way but it is best to get used to a

certain method e.g. out toward the wheel for the front (leading) and back

toward the wheel at the rear (trailing) then when you adjust next time you

turn the same way and get immediate results.

§

Turn the adjuster

until the shoe just locks the drum, then in the opposite direction to

loosen until the wheel just turns freely.

§

There is a very

small difference between just locked and turning freely.

§

With the wrench held in place on the adjuster,

retighten the adjuster lock nut. That is why we left the ring spanner in

place!

§ Systematically do

all wheels should take < ½ hour or maybe an

hour maximum with a

couple of stubbies (beers).

Major normally done after dismantling and some

serious type maintenance with the vehicle on stands and wheels

off.

Adjusters in cam off position

Turn both down at

the dimple to start your major adjustment

Adjusters in cam off position

Turn both down at

the dimple to start your major adjustment

§

This adjustment

realigns shoes with the drums after re-line, drum skimming, new drums and

the like.

§

OEM drums are

slotted to fit feeler gauges to measure clearances; some aftermarket drums

do not have these slots.

§

One could drill a

small hole (1/16”) depth

limited in each drum so that wire gauges could do the job, being extremely

careful not to drill into the finish drum to shoe bore.

§

All the IMPORTANT

things done?

§

If the drums are worn and linings are scored go

straight to the section NO SLOT METHOD

§

You can do your

minor adjustment as related above and the top major reading .008” should be pretty right but

recheck anyway.

§

Major Adjustment is

accomplished by turning the anchor pin dots toward each other and then

down until the shoes are set to the proper clearance using a feeler

gauge

§

The recommended

shoe setting is .008” at the

toe (upper end) and .005 clearance at the heel (lower end) each 25mm

(1”) in from the lining

extremity

§

Loosen the anchor

lock nut on the forward primary shoe (not too much) leaving the wrench

attached (notice how Derek has a permanently modified and shaped a wrench

to fit above).

§

With the feeler

slot or drill hole 25mm (1”)

in from the end of the toe (top) of the leading shoe check and adjust for

.008” by turning the anchor

dot downward

§

Move the drum so as

to have the slot 25mm (1”)

from the bottom (heel) of the same shoe, check and adjust to

.005.

§

Tighten the locknut not allowing the anchor bolt to

move while doing so otherwise the adjustment will alter

§

Check for drag and

if dragging do again

§

Mark locknut with

chalk when done

§

Then do each other

shoe on the vehicle the same way remembering that the trailing shoes are

shorter so the position of the feeler will be different

NO SLOT

METHOD

§ I will offer

another method not requiring the slots or drill holes lifted from a WWII

publication related to light Chevy Blitz trucks (thanks to Jimmy Sewell,

an old buddy from TAFE days) which is simple, quick and easy. Presumably it

will work on Ford GPW’s with

no ill effects from cross pollination, envisaged!

All the IMPORTANT

things done?

Do your minor

adjustment as related above

§

Apply a force of

25-35# to the brake pedal. This force must be consistent and maintained

through out the entire adjustment.

§

This is not much

force; place a small piece of wood in between the pedal shaft in the

engine compartment and the firewall holding the pedal down slightly and

consistently just past free play.

§

This force moves

the m/c piston enough to close the compensating or equalising port but not

move the wheels cylinder pistons!

§

All bottom anchor

pin dimples should be as close as they can be together (adjacent to one

another)

§

When their locknuts

are loosened we use the system of leaving the ring spanner (box wrench) on

the anchor lock nut as we did above

§

Adjust each of the

8 anchor pins (in turn) moving the dimple downward with no more than

3” long wrench until the shoe

just touches, indicated by very slight interference when turning the drum,

back off a fraction

§

Tighten the anchor

pin lock nut as you complete each one ensuring the anchor pin does not

move and mark as done with chalk

§

Remove the pressure

from the brake pedal and make sure all the brake drums turn with absolute

minimal to no dragging

§

If the shoes drag

you need to do it again. Be more careful this time as 4 stubbies

(beers) affects concentration!

§

Road test when

under .05 in an area with little traffic. After a little bedding in try a

few repeated hard applications.

§

Pulling up in a

straight line ?? you’re

a winner!

Sketches and

diagrams are courtesy of the odd g503.com post, Bendix, Snap On and

TM’s.

Jeep MB/GPW Foot Brake Major adjustments made simple [diagram 1]:

Brake shoes must be concentric with drums. This can’t happen with skimmed drums & standard shoes

[see diagram 2]

1. Turn all cam adjusters to fully retract all shoes

2. Turn all bottom anchor adjusters so dots [or arrows] face one another

3. Turn anchor in direction of arrow/s until the shoe heel/s drags on drum

4. Turn top cam/s in the arrow direction of the arrow/s to bring the shoe into contact with the drum.

This will cause the shoe/s heel/s to lose contact with the drum

5. Turn the anchors again in the direction of the arrows until the shoe heel/s just drag on the drum/s again

6. Repeat step #4

7. Repeat step #3 & #4 until cam adjustment no longer frees the shoe/s heel. Then tighten the anchor bolt nut/s

8. Repeat procedure for all shoes if you have not already done so

No table can cover all

know issues.If you have more to add, suggestions, comment please feel free

to do so by contacting the poster. Go to g503.com and PM User

Name artificer

|

Problem

|

Component Part |

Cause/Probable Remedy |

|

Brakes

drag all excessive drum heat maybe

lockup

|

Master Cylinder |

Insufficient free play adjust

actuating rod and check return spring fit

|

|

Brakes

drag all or some

|

All or any Hydraulic Cylinders

|

Mineral oil contamination |

|

Brakes

drag all or some

|

Wheel Cylinders |

Sticky/rusted/gummed hone or

replace

|

|

Brakes

drag all

|

Blocked Compensating or

Equalizing Port |

Either of above or dirt and

contaminants in reservoir

|

|

Brakes

drag all or some

|

Brake Shoes |

Improper adjustment Check and

adjust

|

|

Brakes

drag all

|

Brake shoes

Wheel & Master Cyl. |

Rusted up from lack of use. Major

overhaul |

|

Brakes grab & pull to one side |

Brake Shoe/s, Linings |

Oil/brake fluid/return spring/

adjustment

|

|

Brakes grab & pull to one side |

Brake Linings |

Different materials on same axle

|

|

Brakes grab & pull to one side

|

Brake Linings |

Leading &

trailing shoes reversed on one wheel

|

|

Brakes grab & pull to one side |

“U”

bolts, wheel bearing/s loose |

Check and re-tension |

|

Brakes grab & pull to one side |

Brake Drums |

Machined, scored or worn

differently. Repair - replace

|

|

Brakes grab & pull to one side |

Tyres or Wheel alignment |

Check pressures and tyre wear |

|

Pedal hard poor

brakes

|

Linings

|

Glazed. Sand paper or emery lining and

drum

|

|

Pedal hard poor

brakes

|

Lining/s |

Oil soaked. Replace in pairs |

|

Pedal

travel too far

|

M/C push rod or spacer

missing

|

Adjust free travel check and

replace spacer

|

|

Pedal

travel too far (hard)

|

Brake drum/s |

Worn scored out of shape. Check

machine or replace in pairs

|

|

Pedal

travel too far (hard)

|

Brake shoes |

Pump fast, comes up and hard.

Adjust

|

|

Pedal

travel too far (soft)

|

M/C, W/C, Hoses or Steel Lines,

Flaring and Fittings

|

Air in system. Find and repair

leak/s replace damaged parts. Adjust and bleed |

|

Pedal

travel too far (soft)

|

Linings

|

Loose rivets, replace linings

(pairs) or re-rivet

|

|

Pedal

pulsates (usually hard) on application |

Drum/s |

Out of round, oval. Check,

machine or replace (pairs)

|

|

Brake Squeal

|

Drums/linings |

Ingress of dirt and dust. Clean

|

|

Brake Squeal

|

Linings

|

Loose, glazed. Remedies listed above |

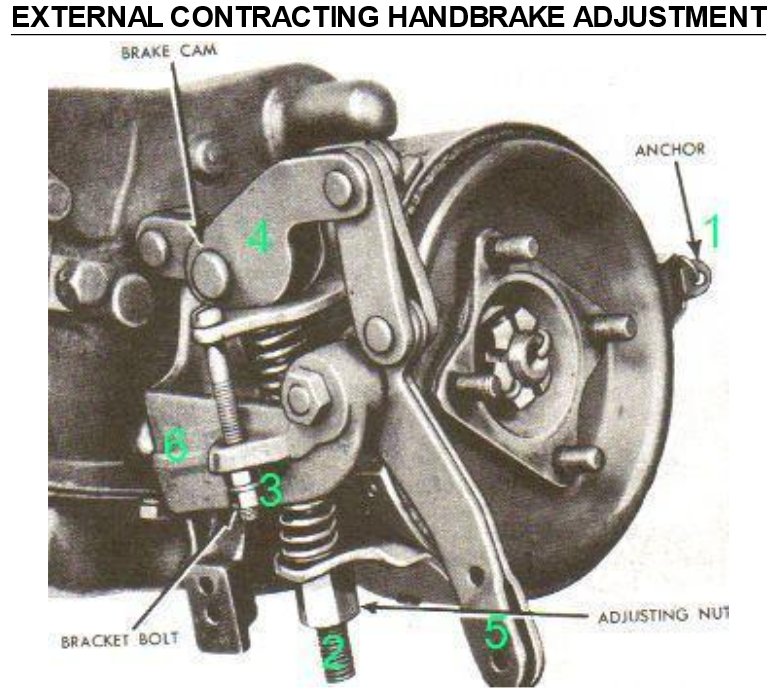

The handbrake adjustment

is not difficult, and this type of park brake system is very effective if

properly adjusted.

One thing to be aware of

is that many people have played with your vehicle before you and there is

no guarantee everything is it's proper place, or, is to specifications and

some bits may be missing

altogether.

The handbrake adjustment

is not difficult, and this type of park brake system is very effective if

properly adjusted.

One thing to be aware of

is that many people have played with your vehicle before you and there is

no guarantee everything is it's proper place, or, is to specifications and

some bits may be missing

altogether.

1. Check the operation of

the the handbrake lever and pawl locking mechanism. Note:- When applying

the handbrake always turn the handle 1/4 turn (the same you do when

releasing) then turn back to lock when application is complete. This will

save Pawl wear & tear.

2. Establish that all

cable attachments are in place, tight, and that the outer cable is firmly

secured at the fire wall and other extremity.

3. Lubricate between the

inner and outer cables, ensuring free easy movement. ( This lube should be

done as an ongoing service

basis)

4. Disconnect the cable at

the Drum end. This ensures the cams(4 of) etc. are all in the off

position.

5. Check the brake band is

in place correctly, correct springs and all hardware

attached.

6. Elongated or oval holes

and worn clevis pins (4 & 5) and such may need components and holes

built up, re-drilled and pins

replaced.

7. Anchor (1) is your

first point to adjust and there are two things of importance. Clearance

between the transmission lug to band attachment should be no more than

0.005". If larger, remove the band and adjust the gap by squeezing in a

vice, gentle persuasion or other suitable method. When fitted there is

between 0.005" and 0.010" drum to lining at that anchor. Lock wire must

not be overly tightened or

binding.

8. Adjust Nut (2) until

the Lining just binds with the

Drum.

9. Adjust Screw (3) until

the head engages on the Band and the Nut and Locknut are just snug against

the Bracket (6) Clearance should be around 0.010" when this

happens.

10. Back off Number 2 Nut,

two full turns, or give the Lining approximately 0.010" and the Drum

should turn freely.

11. Re-attach the cable,

and if it doesn't match up properly, the outer cable positioning needs

altering so everything lines

up.

12. The original MB/GPW

cable was not adjustable, but by now, modifications done so that it

can be.

13. This brake is meant

for parking and should not be applied when the vehicle is in motion unless

in an emergency situation.

14. The faster you go the

harder they wrap on.

15. Regardless of what

some may think, they are very efficient and serious damage may occur, I

have struck a tail shaft that looks like a corkscrew, so be

aware.

If you don't have any

hassles, it should take less than 20 minutes to obtain the best

results.

John

Gibbins.