|

- FOCUS ON TRAILERS - The Willys MBT Restoration.

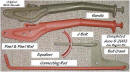

Purchased for AU$500.oo (US$270.00) sight unseen, and thanks to Harry Cislowski sending me an email, I was fortunate to buy this Willys MBT at such a low price. It doesn't look much at first glance, but I believe it's a diamond in the rough, and will restore very nicely. The basics are there, the frame is in great shape, the original axle, lunette, and one hook and chain are present, but the tub is 80% shot, but mostly original, having had the front panel replaced at some stage. Both fenders are in need of lots of attention, but there's two combat rims in reasonable condition, the two "civvy" tyres are throw a ways. No handbrake or cable and no light switch. Harry, Thanks mate....a typical Queenslander, always there when needed, I can't thank you enough. CLICK ON THE THUMBNAIL TO OPEN The Trailer arrived in the back of Harry's tandem trailer. Bit of a thrill to see, and some shock at the amount of rust. I took an instant appreciation as to it's history and significance, and immediately fell in love with it. This was going to be a slow process if I wanted to do it justice, but anxious to start. Within the first hour of Harry leaving, Patch and I had found the numbers, exactly where it was expected to be, the left side front frame spring gusset. 19433W . A very Early 1943 MBT. A few little surprises, some of the original pal nuts were still in place, original shock absorbers, Willys springs, and almost all bolt heads have the Willys "A" marking. First job was to see if there really was a hook attached to the disappearing chain, and there was, a little worse for wear, but it's a start. Beautiful, original Lunette, shame about the nut. The lunette was frozen with rust, not having seen grease for untold years. It was rather strange finding the hook tho'., as it was jammed up in between the space where the landing leg had been removed, and covered in years of built up hard packed mud. Being a bit worried about the condition of the Lunette, Patch and I took some time to get it out, as it was totally frozen into position, using a decent sized length of bar and a 2' long engineering wrench, we finally managed to get the lunette to turn, and the nut removed. Patch volunteered to do the blasting. After masking off the ground surface of the taper, Patch had a ball, we also blasted the spring and washers. Here's something to think about, if you wedge a screwdriver into the gap where the spring meets at each end, you can get every bit of rust removed. The taper was then linished and repainted. First job done. 7th

October - Next was to see if I could find a landing leg

casting, almost impossible at the moment, so I thought I'd have go at

making one. On Friday after lunch, I drew up the casting from a borrowed

one, and rushed over to the steel fabrication shop just before they

closed, bought some scrap pieces for AU$5. came home and started to cut it

out. All Saturday was spent, cutting and 12th.

October The Landing leg is progressing , having cut the steel to

length, drilled the mounting holes, elongated the rear ones as per the

original, and made the first bend, and that's where it has stopped due to

a In the

meantime, I went ahead and made the locking pin replacement, this turned

out to be a 10 minute job, having picked up a small off-cut of 5/8" round

and some 3/8" rod. It still requires the pin to be machined down I thought I'd try my hand at making a hook, I have no idea how this will turn out, but as "they" say, I won't know unless I try.....here's the first step, the 5/8" plate roughed out there's some serious grinding and filing to do within the next week. 13th

October Managed to get a hold of the Oxy set, and between Patch and

myself we finished off the making of the leg. I was slightly out in my

calculations of the overall length by 1/4", as when finished the leg is

1/8" longer than the original I copied, so I'll have to live with having

the "sexy" long legged MBT.

18th

October - Received a complete NOS Left Side brake

assembly from Bruce Managed to find a right side Brake backing plates to replace the damaged ones that came with the trailer, thanks again to Bruce Teterin. It's coming up from Sydney, and I should be able to pick it up at the annual Brisbane Swap this weekend. (Update: Unfortunately the bloke who thought he might have one... didn't!... so I'm still on the look out for a right side plate in reasonable condition. See Wanted List Above)

26th

October - Great weekend in Brisbane at the Annual swap meet on the

20th, found My biggest disappointment was not being able to find the right side brake backing plate, but I have a few leads to follow up. Also found NOS axel U Bolts for the shockie/spring brackets, ( Thanks again Sean). In all, a very productive weekend at the Swap. 3rd

November - A mixed week of progress and

setbacks, due to the compressor playing funny games, I spent most of the

time fixing and adjusting it so I could at least sand blast some of the

bits and pieces. The A-Frame braces were removed, and I thought I may get away with some small rust hole repairs in the reinforcing inserts, however, upon closer inspection both sides were near collapse from internal rust where it's probably never seen paint. Using an air driven 3" cutting disk tool, the five welds on each side were cut through, and the insert levered out. So these will have to be replaced after I make some new ones. The good news is that the braces show very little pitting, and are sand blasting up nicely. I've drawn the reio inserts and the brace, so making and reinserting the reio. won't be a problem. I'll prime both pieces before re-assembly, and clean up only where I'll re-do the five welds on each side, this should give the braces the best chance of remaining rust free into the future.

In the

meantime, the tub was turned over and the frame inspected, that's when you

realize there 17th

November I've spent the whole week blasting a spring set and the

Monroe shock I

was surprised to find that the Monroe's are usable, just requiring a light

sand blast and painting, new rubbers are arriving this week. They've been

the easiest part so far to fix. The Willys spring straps are 24th November Both springs sets are now blasted, pivot bushings replaced, reset, primed ( one painted) and strapped. I decided to make the spring straps after some consideration, as they were easy enough to make, and no problem to fit. I managed to find some new bushings for the pivot , being modern, they were not brass, they were exactly the right size.

The Restoration Begins 8th

DecemberSpent

the last two weeks making cross members and gusset plates, sandblasting

parts and welding up the side reio plates. Fixed the compressor, so things

are running smoothly again.

I'll have to fix the mid-rear X-member in first before replacing the front-mid X-member to ensure the frame doesn't twist. I've made new ends for the side reio plates and pics will be posted when completed I finally found a right side brake backing plate, just 2km's from my home, a friend over the other side of town realized he had NOS plates for his trailer restoration, so with some horse trading I managed to secure his old one, along with a Handbrake ratchet bracket, but unfortunately no handbrake to go with it, Al is looking in New Zealand for a handbrake lever, probably from a Model A Ford, the pressings are the same, just the top part of the lever needs to be shortened. The 1/4ton Trailer Drawing List on JeepDraw has been updated over the past week, if there's any drawing you need for the parts I'm making for this trailer you can find the available drawings there. 15th December I decided to replace the rough home made right spring bracket with something more closely resembling the original. I had hoped to use the old rough one, as it's only redeeming quality was it was exactly the right distance between the two sides.... that is 1.750", but unfortunately, it was too short in height and almost 1/2" to short where it mounts to the frame. Using the original from the left side I drew up a replacement, had a local steel shop do the bending and proceeded from there. The bracket was completed on the 18th Dec. ( Last pic on the lower right)

Having spent Christmas and the New Year break on making an Oxy cart and restoring an old arc welder I'm now ready to tackle the rest of the trailer without the usual hold-ups waiting for the use of this equipment. Sean Elliott in Brisbane, came up between Christmas and New Year to lend me his Oxy gear on a semi-permanent basis as he hadn't used it in years. Then when Sean decided he was going to print his speedo and gauge faces, and I had a spare printing machine handy, we decided to make it a clean swap, oxy gear for the printing machine.. we both win that way. I made the Oxy cart from an old square tube chair. ( It's a bit obvious when you look at it, but it will do the job), and the wheels came off an old lawn mower. The following weekend I purchased an old arc welder for AU$85 which included all the safety gear and AU$50 worth of rods, a real bargain. Having

sorted out the welders I immediately finished off the side reio plates

that have been hanging (APRIL - JUNE) HAND BRAKE ASSEMBLY FABRICATION I've been fiddling with the idea of making my own Hand Brake assembly for some time as it's almost impossible to find one. Luckily for me a mate over the other side of town had an NOS one, including the handle, I was able to borrow. So I knocked up some drawings and proceeded to go through what was involved. Thanks to Al Brass who let me in on how to make a form die I figured the rest would be easy enough to go ahead. Due to work commitments this has taken longer than it should have, the form die took about 4 hours to make and the rest about another 4 hours... Not bad for a days work. The top part of the handle came via. Al Brass in New Zealand, it's from a 30's Ford Model A. The difference between it and the regular Bantam/MBT are the indents to hold the pawl rod spring. The Model A handle has a tube insert for the spring and doesn't require the indents. All the drawings are available through the JeepDraw 1/4ton Trailer Section

The above pics show the finished Handle, and home made assembly. Completed 8th June R eceived the bearings for the wheels from Ron Fitzpatrick Jeep Parts, along with a complete set of bearings ( wheels, gearbox, t/fer case, the lot) needed for the GPW jeep. Received the handbrake pivot bolt from Paul FitzGerald in the US. At long last I finally found the elusive right side brake backing plate, on Ebay of all places, it should be here in a few weeks and I can carry on with the restoration. Purchased an MD Juan tub, impressed with the panels so far but not their frame/chassis and A-Brace beams. I didn't really want the frame/chassis. (SEP-OCT)After a hiatus of a few years and now retired, I decided to get back into the trailer, so in the past few weeks I've done some work. First up to test the folder I made, the Tail Light Brackets,

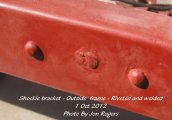

worked well. The Shockie Brackets on my original frame were toast, so not wanting to pay someone to cut and fold the brackets I decided to make them myself. I started by going to the local re-cycle centre, picked up some work hardened flat steel ( old slasher blades) to make a folding blade, ground a V into some 1" block and after cutting the plates, pressed them in my 20 Ton press. They turned out Ok, actually I was surprised how well I managed to get them to match the originals. The shaft was turned on my lathe, along with the spacer. A few welds, a few holes and rivets and I was back on track. The difference between my early Willys MBT, and later Bantam and Willys mine were simple reverse folds and no extra fold to the frame rail, making my job so much easier. The early Willys brackets are welded to the side rail as shown, duplicated, right down to the daggy welds, no aditional effort required there.

The Dreaded Drain Hole Installation. Been putting this off as I though about it, but having bought a 20 Ton press for the shed, (Very Cheap, Thanks John G. Artificer on the Gee) I thought. ..Why not give it a go. Made a die set, did a test on some card to check the debth and crush on the edges, then stamped out a plate, it worked well but did get some stretch areas outside the die area, an easy fix, I just cut the sheeting to the diameter of the die and transfered that to the tub. Used that then to mark the correct location on the tub floor and cut it out with a jigsaw, so easy. Come to think of it, this, in a smaller scale would work to make the recesses for the tool box locks on the wheel well sheeting, but that's for another day. Held the new piece in place with magnets until the first spot or two with the mig, then teased up and down until the edges lines up. Completed with stitch welds, ground off the excess and a coat of primer until I make the part which is attached to hold the drain plug. Might have to make another set of dies to form the next piece that holds the drain plug. Making the bracket holding the Drain Plug to the floor presented a new challenge, all I had to go on was a photo or two as my old one was completely rusted away. Completed and attached 27Nov 2012 On furthur investigation it would appear that Willys used a slightly different shape to the flange and the attached tags. See this Topic on the Gee. Currently making a few new dies that will, I hope get things right. (Fixed Nov 27 Above) Realized that

the hand brakes

were missing the actuator, so being so hard to find, I decided to make one

from the only original I had. Painted in black primer

Front Cross member had a 8mm bend inwards, so used a car screw jack to bring it back. Fitting Tub To Chassis |