|

REBUILDING THE ENGINE

- PART 3 -

- John Barton -

The main and connecting rod bearings used in the jeep engine are two semi

circular halves called inserts. When installing these in the block and

connecting rods, some care must be observed. If there is good clean oil, and

the engine is not abused, they can last a long time. As long as there is an

oil film, the rate of wear is slow. Grit or dust getting into the oil,

either through the carb, or from installation, can ruin a bearing. In my

pictures, you can see that I use a lot of assembly oil. But, by having

everything ready…I get it closed up quickly. I wipe up excess- no oil

should get on threads or bolts…to get proper torque, they need to be clean

and dry. Wipe down all bearing surfaces, there should be nothing behind an

insert.

1

This is how the crankshaft comes from the machinist. Leave it in the bag

until ready to install. The journals are precisely ground and polished.

Scratches, etc are no good, and they will rust in a minute. The tag

indicates that this crank was cut .040 undersize on mains and rod journals.

From old inserts, you can see what old size was. This crank was .030/.030.

So it was cut the minimum, increments are usually .010.

2

As with the valve train parts, I lay out everything. I assemble pistons

first.

3

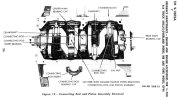

The pistons must be assembled with T-slot and squirt hole in correct

relationship. They must also be installed in cylinders with offset in

correct relationship to main bearings. The connecting rods may be numbered,

check during disassembly. The numbers, letters, dots, etc. can be on either

side. You can’t always use them as a reference. Cylinders are numbered

1-4- front to rear. Often one rod has been replaced. So, you must use

correct assembly and offset to install. As shown in part one, pistons often

have an arrow on top pointing to front. Use the arrow, slot, squirt hole,

and offset to check that pistons are assembled and assigned correctly.

4

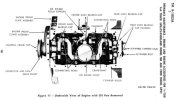

Scan from CJ manual that shows correct piston assembly.

5

These new pistons came with wrist pins. Place connecting rod in vise leaning

away with lock bolt on top side. Slide wrist pin into piston, lining up slot

with bolt. Place piston on connecting rod and finish pushing wrist pin

through. The torque setting for the lock bolt is 35 lbs. I don’t have a

torque wrench that will fit up there. I snug it tight. You can use a

crow’s foot on a torque wrench and do the math etc. I also lube each pin

in the piston.

6

7

I leave piston in vise to install rings (straighten it up). Rings come in

different styles, but are generally same shape. There is usually an

instruction sheet, or the packages are labeled to show which ring goes in

which groove. The widest is the oil ring, it can be one piece or three

pieces, and it goes on first in bottom groove. Two different compression

rings go on next, see picture and explanation from scan. Most rings have a

dot or TOP, but you can figure it out from shape. The ring expander tool is

cheap. Rings are brittle and will snap if twisted or opened too much, Open

only enough to fit over piston. No ring goes in top groove. If using old

pistons, clean all grooves. Use an old ring, break it, or buy a groove

cleaning tool. Most manuals show measuring the ring gap, and the play in the

groove. I check a few of the rings by installing a piston head half way down

a cylinder, inserting a ring on top and seeing that they are close to specs.

I’m using new pistons, new rings, and a machine shop I trust. I do not

measure every single ring.

8

9

The gaps in the rings must be staggered around the piston- 120 degrees from

each other- do not line them up as in picture.

10

Picture of new rod insert in a rod cap. There is a notch that must be lined

up. Inserts come with a spread, so it will stay in place. To set it in

place, gently tap it on a flat surface. As mentioned above, it must be clean

behind insert. Most modern inserts have two holes in both halves, one of

them lines up with squirt hole in connecting rod top, not necessary in cap.

The old insert show the worn bearing material flaking away and scorched.

11

Install upper shell (interchangeable) in connecting rod. Notch and squirt

hole have to line up. Connecting rods should have been cleaned, but check

that squirt hole is clear. Cover the bolt heads with cut off piece of

3/8’s rubber hose. The fit down the cylinder is tight, big fat pieces of

hose will not work; these are part of an old air line.

12

I lay out the crank with inserts. I’m pretty liberal with the assembly

lube. Buy the time I close up the crank case, every galley in block and

crank will have been squirted a couple of times. Wipe up excess when

installing caps and bolts etc. Clean threads for torque!

13

Put the upper shells in the block, some brands are labeled with a U or L.

The front bearing has a flange- to control thrust. The rear has two grooves.

So you can figure out which goes where by lining up oil galley holes and

dowel pins. In earlier pictures, the dowel pins where in place. They usually

don’t fall out. Clean around them; make sure bearing surface is clean and

dry.

14

Here is a picture of rear main cap with dowel pin out. The front cap does

not have a dowel pin, the flange prevents the bearing from spinning, and

there should be five dowel pins.

15

Picture of old insert. Again, you can see the flaking metal.

16

Spread some assembly lube evenly on the inserts in the block and the caps.

Put the rear main seal in place (pictures below), lay the crankshaft gently

in the block. Put the flywheel bolts in crank rear flange. One you put the

rear cap on…you won’t be able to get them in! Just before I put the caps

in place, I squirt more lube down the crankshaft oil galleys. The assembly

lube, with STP will stick and stay until engine start-up.

17

This is how I turn crankshaft. Hand tighten the main caps, turn crank one

complete revolution. From now on, every time you tighten a main cap bolt,

turn the crankshaft one complete revolution. I start with middle cap, torque

to 50 lbs- turn! Either one of the other caps-turn! Last cap-turn! The first

time you do not turn for each tightening, if there is a problem-it will

bind, and then you need to start backtracking to find the problem. Now

torque to 65 lbs, again, turning between every bolt. You can put the front

crank nut on and use a ratchet and socket to turn crankshaft. Either way is

fine. When all the caps are torqued, and all have a lot of assembly lube,

you should be able to spin the crankshaft with one or two fingers on a

regular ½ inch drive ratchet on the front nut. Note the rubber dowels that

fit in the drilled hole between cap and block. Just before putting pan on, I

coat these in indian head shellac and insert, the pan compresses then to

seal. I also use a little on rear cap mating surfaces.

18

19

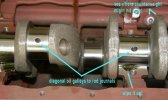

Picture of lube on journals, spread it out. Picture of diagonal oil galleys

in rod journals. I always squirt more oil down because of turning, plus as I

said a few times now…I want all the parts covered with assembly lube when

I start it for the first time.

20

Picture of the three types of rear main seals. The rear main cap has a large

groove that the oil slinger on the back of crankshaft fits into. There is a

drain hole there for oil to flow back to sump, make sure it is clear. The

smaller groove toward the back is for the seal.

21

Picture of the asbestos rope type seal. Still works, I have used them, they

need a little care and attention when installing.

22

Picture of the rubber seal that was used for most of the service life of

jeeps.

23

Picture of the modern, metal supported, wider rubber/neoprene seal that

comes in most new gasket sets. I have seen or used them all. They work

equally well, the newest one is more forgiving of a rough or worn surface on

the crankshaft.

24

Main caps installed and torqued down with first piston coming in. For

crankshafts, many manuals show checking clearances with plasti-guage, etc. I

use it, but more to check working engines to see why or where oil pressure

is going? Again, This is new bearings, new crank, and a machinist that I

trust. The front gear sprocket stayed on this when it was ground, so I did

check the endplay per the books. It was ok. The rubber on the bolts keeps

them from scratching journals, but you still need to guide them by hand.

25

The ring compressor is a ratcheting sleeve that pushes rings into grooves so

that assembled piston can be inserted. Use a wooden hammer handle to knock

them down.

Wipe cylinder walls clean, use assembly lube on rings and compressor before

tightening it down. I still have the block on a wooden bench, but you might

find the engine stand easier. I put all pistons in from top just so rings

are in. Then with block on side, I can reach and pull rods into place or

control them while I knock from top. Do 1 and 4 together, 2 and 3…so the

journals are up or down together. Just before putting connecting rod on

journal, more lube. Squirt in galleys and rod cap, then snug it in place.

The torque for connect rod nuts is 50 -55 lbs. I do it in 35, then 50 lbs

steps. Again, rotate crankshaft a complete revolution between each step, and

between each cap. As you connect more pistons, and with the added resistance

from the rings, the crankshaft should still spin.

You should not need to push hard. If, on one of your tightening sequences,

it does bind,

you have problems. I once got a set of rod bearing with one odd size out of

the eight!. I wasn’t turning between every nut or bolt….darn! There are

other things that can happen.

A bent crankshaft is usually picked up by the machinist. But, bore mis-alignment

on the main bearings has happened. Old engines take a set, fatigue, over

heating!!

26

Two scans from manuals, the first one is from 1803A, and is wrong! Every

other picture and description is fat side away from nearest main bearing. It

took me a while to reconcile this the first time I rebuilt an engine. I

didn’t have all the other books, and this didn’t make sense with T-slot,

squirt hole, etc. Also you will find some assembled wrong, the engine runs,

just has more piston side play wear I guess?

27

Rods 2 and 3 with correct offset. Fat side away from nearest main bearing.

28

MISSING PHOTOS 28 Substituted

These connecting rod bolt nuts are the split locking kind. If you have a

plain hex nut, you should use the PAL nuts.

29

MISSING

PHOTO

I put this picture of using the torque wrench in to show that the engine

must be secure whether on a bench or on a stand…it will tip over.

30

Clean the float well, install gasket and tighten it down, and check that it

doesn’t hit crank in any position.

31

Put the pan on.

I appreciate the nice comments on earlier posts, but I can’t be the only

G503’r that rebuilds engines? Others must have tricks or short cuts or

better ways? I put this out to learn as well as show new people. Is this the

way you do it? I will post the costs later, but what do others do- send it

out? I’m sure others besides myself would like to know. It is a forum.

Thank you, John

Home

John Barton's Engine Rebuild 1

2

4 g503.com

|